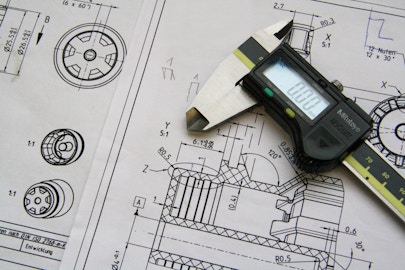

Mechanical Engineering

From Concept to Reality—Fast

Great electronics deserve great enclosures, interfaces, and mechanical systems. While we’re not industrial designers, mSemicon bridges the gap between circuit boards and physical products with agile prototyping and smart mechanical solutions.

Our in-house 3D printers, CNC machines, and temporary molding tools let us test, refine, and validate mechanical concepts in days—not weeks—saving you time and costly late-stage redesigns.

Our Mechanical Capabilities

Rapid Prototyping

✔ 3D Printing & CNC Machining – Turn sketches into tangible prototypes within hours.

✔ Concept Validation – Quickly verify (or discard) ideas before committing to tooling.

✔ Iterate at Speed – Refine ergonomics, fit, and function early in the design process.

Fail fast, learn faster—with minimal cost.

Temporary Molds & Low-Volume Production

✔ Functional Prototypes – Test near-final designs with temporary molds.

✔ Material Insights – Identify performance issues before mass production.

✔ Bridge to Tooling – Confidently transition to high-volume manufacturing.

Catch flaws early. Perfect the design later.

Volume Production Support

✔ Tooling Coordination – Partner with trusted suppliers for high-volume moulds.

✔ Design for Manufacturability (DFM) – Optimize your part for cost and quality.

✔ Machined Solutions – Ideal for low-volume or precision components (no tooling needed).

We handle the logistics—you get production-ready parts.

Why Partner With mSemicon?

✅ Speed to Prototype – Validate ideas before heavy investment.

✅ Pragmatic Approach – No over-engineering; just what your project needs.

✅ End-to-End Coordination – From first print to final production.

✅ Electronics-Mechanics Synergy – Seamless integration with your PCB designs.

Let’s Build Something Physical

Whether you need a prototype enclosure, a custom bracket, or a low-volume machined part, we’ll help you navigate the journey from CAD file to finished product—efficiently, economically, and without surprises.

Got a mechanical challenge? Let’s prototype the solution!